Needed to make a brass gas tank for my hit & miss engine and thought you guys might like some pictures. Experts might find the photo's superfluous, but I tried to take enough that it's a bit of a how-to post for someone newer

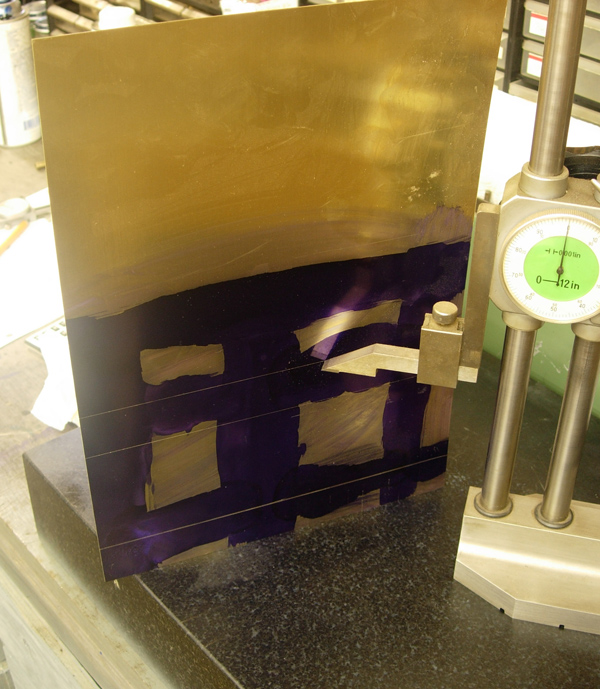

Lazy mans way of laying out the sheet - propped up against an angle plate, the height gauge makes quick work of the layout. Brass is .028 thou.

A lot of the corner material can be cut with good shears, but as the corners will have tabs, you need to get into them with a fret saw. Here's the simple set up for this job

Cutting out the corner with a fret saw

The sheet is now ready for folding. Corners all cleaned out and any required touchups done with a file

Here the sheet metal is held in a home made set of folding bars - just crs, some dowel pins and cap screws.

In the midst of the first fold - I held the bars vertically as the wasn't enough throat distance in the vice to hold horizontally - a more convenient position. Note that the tabs are not folded over at this setting of the bars

This is the right tool for folding the metal over so as to not mare the surface; a leather mallet

Here is a tab that has just been folded. Note how the bars have been moved so that there is about a 1/32 gap between the bar and the side - this will allow the tab to fold up inside the of the side

Here the work piece is ready to have the ends folded.

Hunt through the scrap box for a chunk of metal to fold against and that will fit in side of the box. Here the end is being folded. Note how the tabs tuck neatly inside of the box.

The narrow lip on the bottom piece is folding using the folding bars

Here's the competed sheet metal work, ready for soldering

Simple solder set up, weight & refractory bricks. Wet paper towel was used as a heat sink around completed joints.

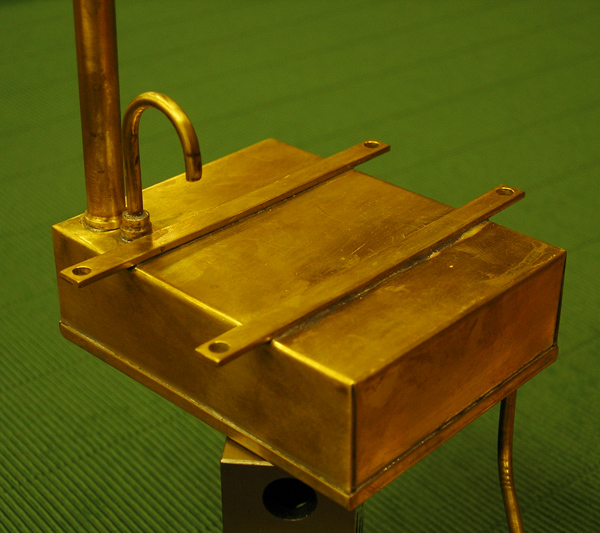

Here a some shots of the competed tank. I had wanted to include shots of bending the pipes and shots of them set up for soldering, but I managed to destroy my camera (arrrg). Bought a new one for these final shots. The pipes were soldering using my 3rd hand design http://bbs.homeshopmachinist.net//Fo...ML/012958.html

Hope its of some value to you