Says Marv:

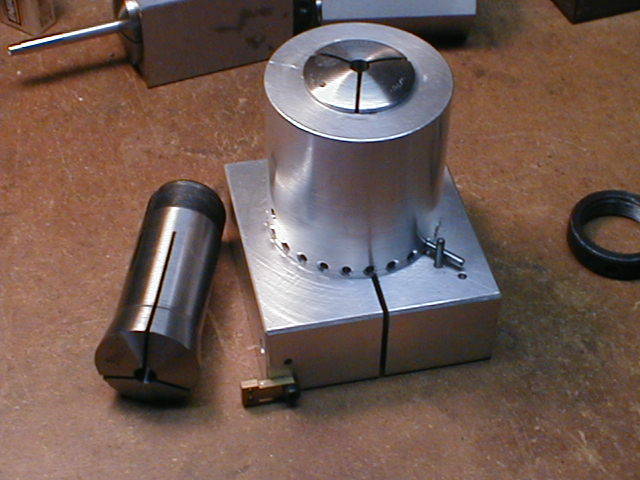

I occasionally need to mount a small part on a faceplate so I made a tiny one to fit into a 1" collet.

The T-slots were made with a 1/4" mill reground to look like a T-slot cutter. The T-nuts are 6-32. The back view,

shows the spigot used to mount it in the collet. The spigot is removable

and has a precision centering pin so that other fixtures can be fitted to it. (A sacrificial mounting plate is shown on the right.)

Finally, with the spigot removed, the faceplate fits into my vertical collet holder (described in an earlier post) to form an indexing table. The bushing shown fits into the table's central hole to reduce its diameter if working on parts smaller than 1/2" OD.

And from the earlier post:

It's a cylinder that holds a C5 collet either vertically or horizontally in the milling vise and provides for 15 degree dividing. The base locks either under vise pressure or via an included (not visible) locking screw. A small stop permits accurate repositioning.

This same base accepts the small rotary table (also capable of 15 degree dividing) mentioned in an earlier post.

Since 90% of the parts I make that require dividing fit into a collet, I find this arrangement very useful for most of my work.

A (internally) threaded ring in a recess in the back of the indexer pulls the collet in to tighten it. This ring has slots into which lugs on a custom made cylindrical wrench fit. This arrangement allows the collet to be tightened with a long piece of stock in it that projects out of the collet rear.

The threaded ring is in a recess so that, when tightened, the indexer can sit flat on its bottom in the vise. There are probably other and better ways to do it but that arrangement worked for me.